As simple as it seems, pipe fabrication isn’t always so straightforward. The majority of pipe in fabrication shops is nowadays rolled, affecting the preheating methods. Flame and resistance heating present numerous challenges and limitations. However, a new option is now available: the Miller Rolling Inductor, which is compatible with the well-known ProHeat 35 Induction welding machine.

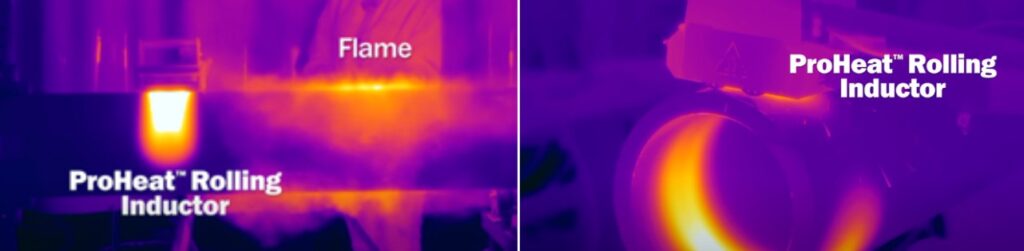

The most primitive method of preheating metal for welding is the open flame, which has numerous risks and disadvantages. Involving gas cylinders, gas lines, hoses, open flame…etc. in workshops or fields introduces considerable heating hazards. Open flame loses the majority of generated heat into the environment and creates unwanted fumes. Controlling flame in an open yard is another challenge especially when it is windy. Induction welding machine technology addresses these issues.

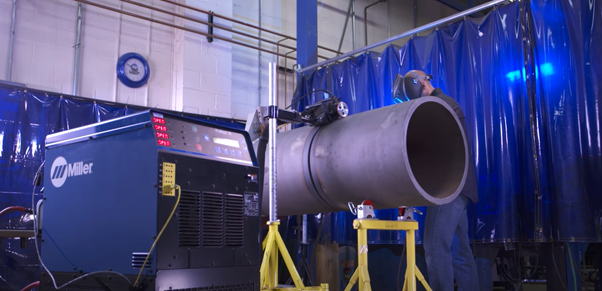

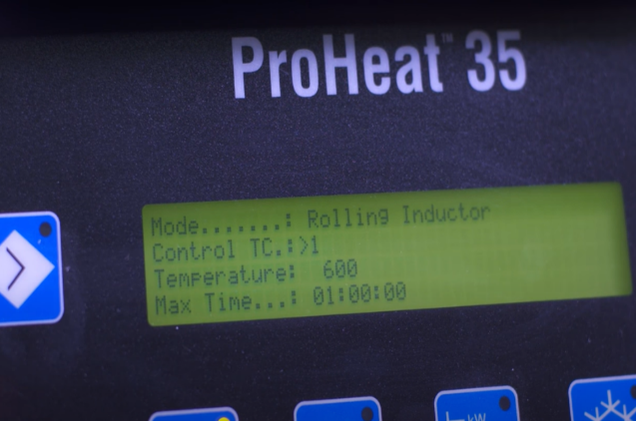

Miller ProHeat rolling inductor is providing the most efficient way to preheat work pieces for a wide range of welding applications from moving parts to plates and pipe compared to traditional methods. An Induction welding machine is easy-to-use, saves money, reduces preheat time, creates a safer welding environment, and allows welders to spend more time welding with the ProHeat 35 rolling inductor. Upon connecting the rolling inductor, the power source detects the connection and automatically activates the appropriate operating parameters.

Continuous fabrication eliminates the need to start and stop to reposition cables and hoses. Without relying on an outside contractor for preheating, this simple system lets you manage your manufacturing schedule and production costs. As a result, you will save money by lowering your overall cost of ownership by using the ProHeat 35 rolling inductor, which reduces labor costs and consumable costs. The Induction welding machine provides unmatched efficiency.

With the mounting arm, the welder can align the induction head on the pipe using a standard pipe stand. Induction heating with an Induction welding machine brings the part to temperature faster than conventional preheating methods, allowing the welder more time to produce welds, as well as being highly energy efficient because little heat is lost in the process. By providing constant heat input to the part and controlled power output, the ProHeat rolling inductor is an effective option for achieving temperature consistency.

To prevent overheating and damage to parts, the system includes a motion detection system that reduces power output if the part moves too slowly. The output is completely turned off if there is no movement or limited movement.

Save money with unmatched productivity. What you need in today’s pipe fabrication world is the ProHeat 35 Induction welding machine with rolling inductors from Miller!

Watch the video here: Miller Preheating Technology for Roll-Welded Pipe Increases Quality, Productivity and Safety

Talk to our expertsCopyright © 2026 | All rights reserved. Designed & Developed by Code & Co