The skill of welding is crucial in various industries, from construction to automotive repair. Nevertheless, welding poses inherent risks, primarily due to the intense light and heat generated during the process. To protect themselves, welders need reliable gear, and among the most crucial pieces of equipment is a welding helmet. In this blog post, we’ll explore the benefits of welding helmets and highlight why the Miller ClearLight™ range stands out as an ideal choice for welders in the Middle East.

The Importance of Welding Helmets

Why Choose Miller ClearLight™Welding Helmets? Up to 4x the Clarity Will Change the Way You Work

The latest auto-darkening lens technology from Miller — ClearLight™ Lens Technology — improves visibility by allowing a wider range of colors through the lens, providing a more natural view while helmets are down. Our lens technology’s superior visibility was measured by the ANSI Z87.1 visibility test.

These helmets utilize Auto-Darkening filters that adjust the lens shade automatically based on the arc brightness. This feature not only provides optimal eye protection but also enhances visibility before, during, and after welding. Welders can easily see their work area, minimizing errors and improving overall quality.

Miller® ClearLight™ 4x Lens vs. Other Lenses (See comparison video here)

When compared to ClearLight™ 4x, the 1/1/1/1 tech in other manufacturer helmets doesn’t maintain the same level of visibility. Our brighter light state makes all the difference.

The Results Are in and There’s a Clear Winner

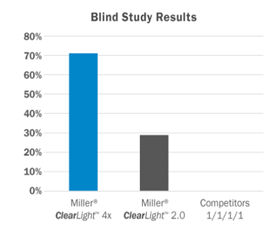

In a recent comparison study of welding lenses among active welders, ClearLight ™ technology was unanimously preferred over 1/1/1/1 lenses.

Blind test Result: (watch here)

Conclusion:

For welders in the Middle East, investing in a high-quality welding helmet is not just about compliance with safety regulations; it is about protecting one of their most valuable assets—their vision and overall health. The Miller ClearLight ™ range of welding helmets offer an unparalleled combination of advanced technology, comfort, and durability, making them an ideal choice for professionals in the field.

Copyright © 2026 | All rights reserved. Designed & Developed by Code & Co