Welding stainless-steel pipes has been associated with the need for purging gas. And it is a process that can consume time and costly.

However, recent advancements in welding technology have introduced a revolutionary method that allows for the welding of stainless-steel pipes without the need for purging gas. In this blog post, we will explore this game-changing technique, its benefits, and its implications for the welding industry.

1. Understanding the Traditional Purging Gas Method

Before delving into the new technique, it is essential to understand the traditional method of welding stainless-steel pipes using purging gas. Welding is performed using a purging gas, typically argon, to prevent contamination and oxidation inside the pipe. Costs are higher, welding times are longer, and additional equipment is required with this method.

2. The Game-Changing Technique: Welding without Purging Gas

The new technique of welding stainless-steel pipes without purging gas has gained significant attention in recent years. This method utilizes a combination of advanced welding equipment and consumables, along with modified welding parameters, to achieve high-quality welds without the need for purging gas.

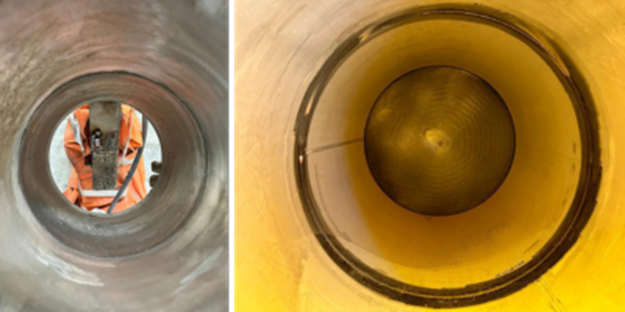

Welders can now save time and, money while maintaining the integrity of the weld. An alternative to traditional TIG welding, Miller® RMD® eliminates the need to purge gas during stainless-steel pipe welding. RMD® is a modified version of short-circuit GMAW, and mainly designed for pipe root pass welding. Shielding gas experiences minimal disruption as it exits the GMAW gun due to its precise control over metal transfer. Through the open root of the pipe, this shielding gas effectively displaces atmospheric air and oxygen. In this way, the weld’s backside does not oxidize.

3. Benefits of Welding without Purging Gas

a) Time Efficiency

Eliminating purging, set up and waiting times will be significantly reduced resulting to a shorter cycle time and a longer arc time. The welding process will take less time and means welders can spend more time on value-added activities. A longer arc-on time allows the company to weld more pipes per day and resulting to higher productivity.

b) Reduction of Cost

There will be a significant reduction in the consumption of argon gas. In addition to improving the company’s profitability, this will directly reduce its operating costs in addition to requiring significantly fewer Argon gas cylinders, and the logistics and warehouse teams will be able to spend more time on other tasks.

c) Increased Accessibility

The absence of purging gas enables welders to work in confined spaces or areas with limited ventilation, where the use of gas would be challenging or even impossible.

4. Implications for the Welding Industry:

The introduction of the technique for welding stainless-steel pipes without purging gas has far-reaching implications for the welding industry and this innovation has the potential to revolutionize welding processes, making them more efficient, cost-effective, and accessible. Taking on previously impractical or expensive projects is now possible for welders.

Conclusion:

Welding stainless-steel pipes without purging gas is a game-changer in the welding industry. This technique offers numerous benefits, including cost reduction, time efficiency, and increased accessibility. By eliminating the need for purging gas, welders can achieve high-quality welds more efficiently and cost-effectively. As this innovation gains traction, it has the potential to reshape stainless steel pipe welding, offering new opportunities to welders and pushing their capabilities.

With reliable welding systems and RMD processes, you will gain a competitive edge so get the perfect Miller machine for pipe root pass welding by contacting us today. We look forward to hearing from you.

Talk to our expertsCopyright © 2025 | All rights reserved. Designed & Developed by Code & Co